The Materials Working Group for the Living Building at Georgia Tech design team is vetting materials and products that can be used on building. It’s not easy.

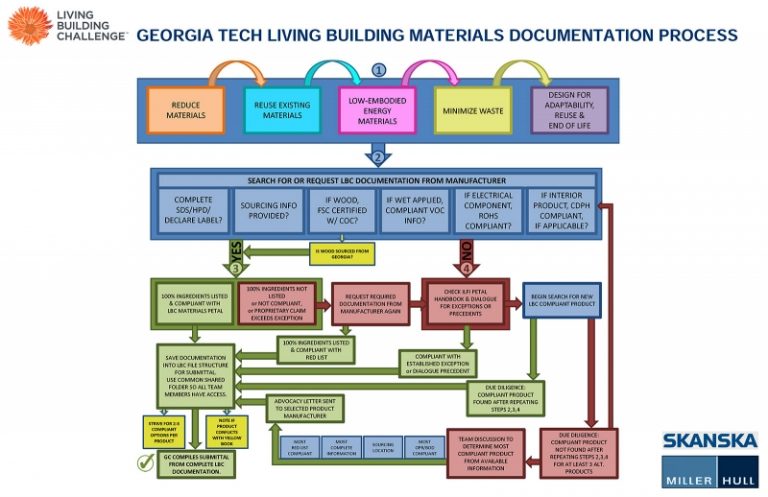

Just look at the flowchart (above) developed by one of the design firms, The Miller Hull Partnership, along with builder Skanska USA. Architects Ramani Koti and Alissa Kingsley report this week on the Lord Aeck Sargent blog that the Materials Petal is “as challenging, if not more, as achieving net-positive energy and net-positive water.”

What makes the Materials Petal so difficult? It’s partly that the Living Building Challenge’s “Red List” drastically limits the building materials that can be used. And because the LBC is so new to the Southeast, a fully developed network of suppliers and products haven’t been systematically vetted for compliance with Living Building standards. At Georgia Tech, that process is complicated by the “Yellow Book” of university design standards that sometimes conflicts with the LBC requirements. As Koti and Kingsley write:

One of the first tasks was the review Georgia Tech’s Design Standards (“Yellow Book”) for the most-required materials and products and their alignment with the LBC Materials Petal’s Red List requirements. While the Yellow Book is very rigorous in mandating environmentally friendly choices, requirements for PVC piping, fluorescent lighting (mercury), and potentially problematic foam products are in conflict with the Red List. Sole-sourcing requirements will be investigated as the project progresses. This project is expected to play an important role in informing future development of the Yellow Book.

The primary focus so far has been on developing a process for vetting and documenting product selections based on Red List compliance.

It’s important to note that the design team’s effort to find products and materials that are available in the Southeast and in compliance with the LBC’s Materials Petal could have broader implications for Red List-compliant buildings across the region. Their work is intended to help build the supply chain and information network that designers of future buildings can rely on.

Want to get occasional updates on Kendeda’s effort to transform Southeastern design and building practices? Subscribe here.