Part 4 in our series on the Energy Petal in the Living Building at Georgia Tech. Read previous article here.

Most of us think of air conditioning as the equipment that lowers a room’s temperature. It’s more complicated than that.

In the Southeast, cooling a net-positive building is likely to be its biggest mechanical challenge. And how engineers for the Living Building at Georgia Tech address that challenge could influence the way other net positive buildings in hot, humid climates handle heating, ventilation and air conditioning.

It’s complicated because of the difference between “sensible” and “latent” heat. “Sensible” refers to air temperature. “Latent” refers to the heat absorbed by matter; it’s the energy that transforms solids to liquids to gas — so it can be stored in the air as water vapor. That’s how we get humidity

The problem is that heating and cooling a room affects both forms of heat at the same time. When an air conditioner draws heat out of a room, it doesn’t just lower the temperature. It unavoidably performs the energy-intensive task of condensing moisture held in the air into droplets of water.

“It’s kind of like the way a beer glass will ‘sweat’ when you have a cold beer in it on a warm day,” says Marc Brune, associate principal at PAE Engineers and the lead design engineer on the Living Building at Georgia Tech.

In a humid climate, the amount of “sweat” (or dew, to be more precise) will be significant. So, if you don’t want puddles on the floor and water draping equipment, your air conditioning had better account for the need to remove that moisture. In warm temperate climates, like Atlanta’s, heat still requires more energy than cooling does; throw in high humidity, however, and cooling becomes the more complex endeavor.

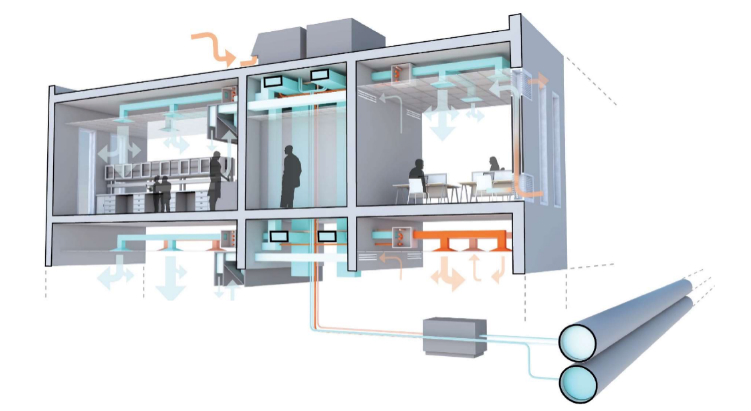

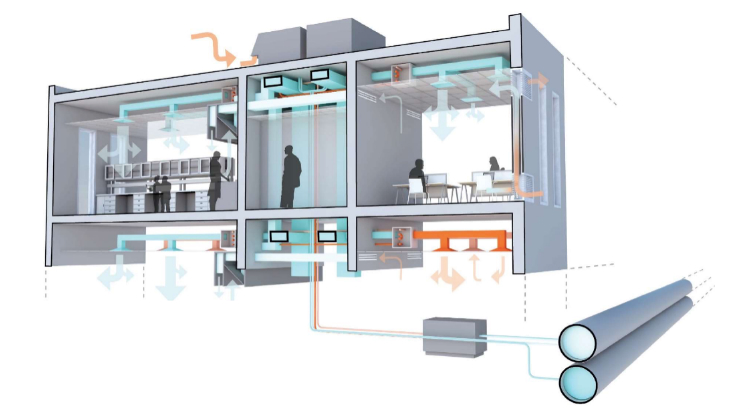

A conventional forced-air system deals with the condensation issue by lumping temperature and humidity together. It blows inside air via ductwork through an air handler where the humidity is condensed, collected and then piped outdoor. But, as Brune notes, constantly circulating vast quantities of air through a building “just isn’t the most efficient way to heat or cool.”

Brune has spent much of his career designing mechanical systems for high-performance buildings, mainly in the Pacific Northwest. He has a legitimate claim to fame: mechanical engineer of record on the Bullitt Center in Seattle. Five years after its completion, that six-story, 52,000-square-foot office still is described as “the world’s greenest commercial building.” Designed to demand about one-fifth the energy of a typical office building its size, the Bullitt Center actually has performed better than that.

So Brune and PAE were quite a catch when they joined the team that eventually won the competition to design the Living Building at Georgia Tech. PAE’s inclusion was part of a conscious effort to spread professional know-how on deep-green building from the Pacific Northwest to the South.

Toward that end, The Miller Hull Partnership of Seattle (the Bullitt Center’s architects) paired up with Lord Aeck Sargent, an Atlanta practice with deep connections at Georgia Tech. The two architectural firms engaged PAE, based in Portland, along with Newcomb & Boyd of Atlanta. PAE is taking the lead on the mechanical, electrical and plumbing design. As the project moves on to permitting and construction administration, Newcomb & Boyd will take the MEP lead.

Brune quickly realized that the Atlanta job differed from the dozen or so low-energy buildings he’d worked on out West. Few net zero buildings — much less net positive ones — have been constructed in a humid climate like the Southeast’s. Other than elementary schools, which are something of a special case, none of the region’s net zero buildings are even half the planned size of the Georgia Tech building.

“The big deal is the humidity,” Brune says. “It creates a different dynamic, especially in a building that’s going to have such an active program.”

Despite Atlanta’s high humidity, the design team isn’t straying far from the basic approach PAE has used on other high-performance buildings. Even before Georgia Tech selected LAS and Miller Hull for the project, Brune and Todd Mowinski, his Newcomb & Boyd counterpart, envisioned radiant flooring to heat and cool most of the building.

“Nothing we’re proposing,” Brune is quick to point out, “is in itself technologically groundbreaking,”

It really is the humidity

If forced air is the hyperactive hare of heating and cooling, radiant flooring is the slow but steady tortoise. From an energy standpoint, it’s much more efficient. But it takes more time to heat or cool the air temperature in a room with a radiant system than to blow the air constantly through ducts and an air handler.

The “thermally active” system planned for the Living Building at Georgia Tech is particularly slow and steady. Under that setup, water (sometimes, with some refrigerant) courses through polyethylene pipes embedded in a thick concrete floor. The liquid medium gradually subtracts energy from the floor when it’s cooling, and adds energy when it’s heating. The concrete mass itself acts as a heat sink for the room: soaking up heat from the space above, or releasing it. Radiantly.

The tortoise-hare dynamic influenced the design team to suggest a more conventional approach for the first-floor auditorium. Radiant flooring may not be the best fit for a room that gets an influx of 170 people, then empties, and a few hours later, might take in another crowd. More occupants mean more body heat, which means more energy needed to cool the room. So Brune and company settled on a displacement approach to the problem — a highly efficient spin on forced air.

A displacement system pulls air though ducts into an air handler, which conditions and condenses the air. The handler then sends that cool, dry air back into the occupied spaces. One big differences from conventional forced air is that the displacement system tightly controls the flow, via low-induction diffusers. A second big difference is that the diffusers are placed at floor level, with the return air being drawn through ceiling ducts. The idea is to stratify the air temperature so that the most comfortable space will be just above the floor, where the people are.

The radiant system will be used throughout the rest of the building. It targets comfort in an even more basic way. Because our bodies radiate heat toward cooler surfaces, a room that’s cooled or heated through the floor tends to feel more comfortable. Theoretically, that means that with a radiant system more people will be more comfortable in a wider range of temperatures.

One drawback is that radiant cooling doesn’t deal with humidity. Rather than circulating air from the room through a handler, the radiant flooring cools the room itself. So, without some way to limit humidity, condensed moisture would create those puddles.

“Our primary dehumidification strategy is to keep humidity out of the building in the first place, ” says Joshua Gassman, an LAS architect and the design team leader.

So the first order of business will be to design an exceptionally tight building envelope, which requires dozens of intricate details to prevent air infiltration. And that detailed design must be followed up by a flawless installation by the builders. It also means entrances must have a double vestibule and an air curtain — a devise that blocks outdoor air from entering by blowing a barrier of dry air down whenever an exterior door is open.

The tight envelope presents a problem that’s become more familiar as commercial buildings have embraced efficiency and performance: If a building’s airtight, outdoor air still must be cycled in for ventilation. Otherwise, occupants and the building itself may accumulate toxins, microbes and air-quality hazards.

Forced-air systems typically ventilate by pulling outdoor air into a chamber where it’s mixed with air being returned to the occupied spaces. But, for ventilation just as for cooling, there are more efficient choices than the conventional approach.

DOAS: A separate path for ventilation

Just before the end of the last century, a small group of mechanical engineers began to advocate for a dedicated solution to the ventilation problem. In landmark 1999 article in HPAC Engineering magazine, St. Louis-based engineer William J. Coad, argued for a separate system to bring outdoor air into a building in a highly controlled way and to dehumidify in the process:

The [separate] system should be a 100 percent outdoor air system and provide all of the ventilation required. It should be the only point at which outdoor air is introduced into the building [and should also] provide all the space humidity control.

Similar systems had been in use already in Europe and Asia. The solution that Coad proposed evolved in the United States into the dedicated outdoor air system, better know as DOAS.

A DOAS pulls outdoor air into a building and filters it at rate calibrated to meet the indoor needs (based on the number of occupants, the activities and the contaminants inside the building). That outdoor air is distributed throughout the building via ceiling ducts used exclusively by the DOAS.

A DOAS typically does a lot of other things. In cooling mode, as the outdoor air passes through fan-like gate called a total energy (or enthalpy) wheel, the moisture and many of the pollutants it carries are spun off and sent up to separate stream of inside air headed through the wheel in the opposite direction. It’s a bit like being shoved from one conveyer belt onto another headed in the opposite direction: Humidity and particles are extracted from the air entering the building, then carried out by the air leaving the building. (To keep pressure inside the building positive, slightly less inside air is sent out than outdoor air pulled in.)

The Bullitt Center in Seattle — where the summer air isn’t so hot and humid — uses a DOAS to ventilate, and to remove moisture and particulate pollution. But the DOAS for the Living Building at Georgia Tech has an extra feature — a salt-like product called a desiccant, that absorbs additional moisture from the outdoor air.

“The key to avoiding those puddles is to extract moisture out of the air before it’s cooled,” Brune explains.

Displacement. Dedicated outdoor air. Radiant flooring. Chilled water. Dessicants. It all sounds very complicated. Brune notes, however, that the system designed for the Living Building at Georgia Tech breaks the complex challenges of heating and cooling a complex building in a hot-humid climate down to manageable pieces.

“Our basic approach,” he says, “has been to boil the system down so that it’s as simple as can be.”

Next week: What qualifies as comfort?